Please Note: CSS Firm is no longer accepting or investigating new knee implant claims at this time. This article is for educational purposes only.

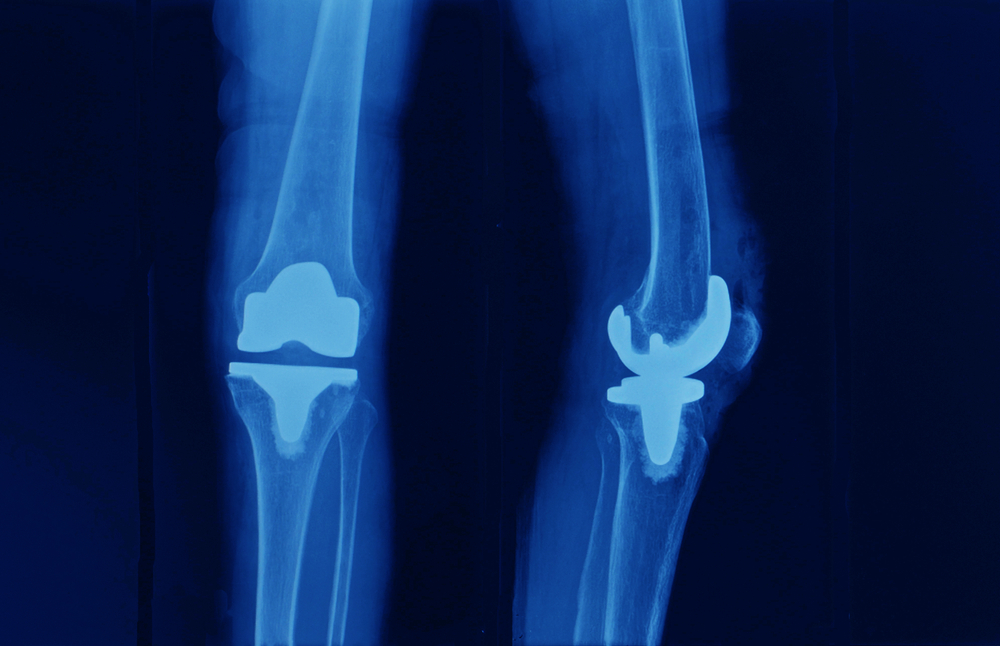

Many knee replacement patients will have little problem after their surgery and rehabilitation, but a number will suffer tibial debonding, usually within a few years of their initial surgery. Tibial debonding in knee replacements can cause the implant to loosen. The debonding occurs at the intersection of the implant and the cement used to hold it in place.

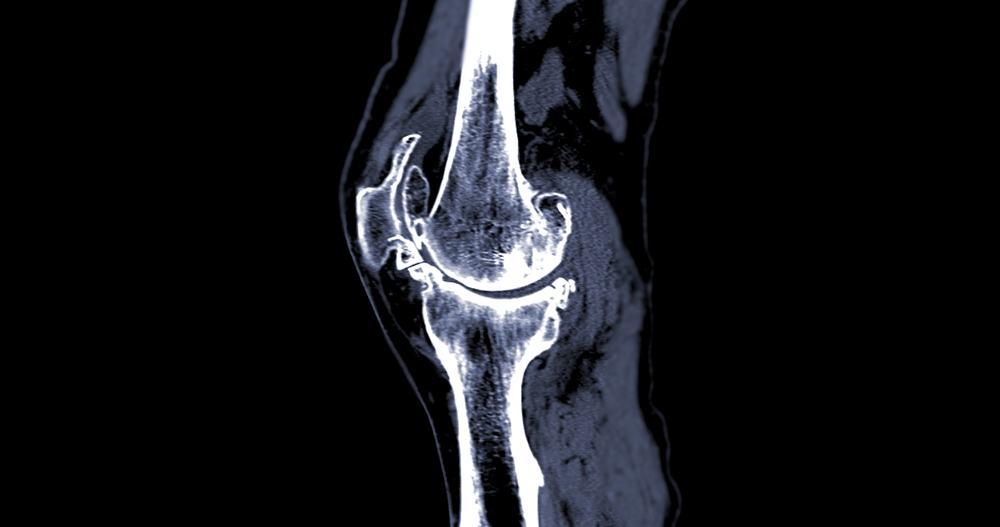

Many times, a patient has no obvious symptoms of a tibial debonding but radiographs can detect the problem and if the issue requires addressing. If tibial debonding occurs, a knee revision is usually necessary. In situations such as these, a dedicated defective products attorney may be able to help.

What is a Tibial Tray in a Knee Replacement?

The tibial tray is a name for the section of the implant used in knee replacements. Most tibial trays are made of titanium, a high-strength metal that is stronger than the surrounding bone. Some tibial trays are made of cobalt or chromium alloys. The metal is bordered with plastic. The higher section of the tibial tray attaches to the shinbone, thus supporting the implant’s upper end.

A tibial tray is generally flat metal with a polyethylene cushion. In some tibial trays, the metal portion may include a stem which is inserted directly into the tibia.

Tibial Tray Cement Application and Debonding

Most surgeons have a particular type or brand of tibial tray cement they prefer to use. The type of tibial tray cement used does not appear to be a factor in tibial debonding nor is the type of implant used. Instead, cement application may be responsible. That does not mean that all tibial tray cements are the same. It takes several minutes for cement to change from its liquid state to a more dough-like appearance and then to turn solid. The process is affected by the temperature within the operating room. Humidity and lower temperatures elongate the procedure.

Cement powder size varies according to the producer and the larger the particle, the longer it takes for the cement to change from liquid to doughy to solid. When the cement is mixed in a vacuum, air is removed, and the time needed to change from liquid to its dough-like form shortens.

How Does Tibial Debonding Occur?

Loosening of the tibial tray cement is the result of various factors, including:

- Later application of cement to the tray, which reduces the bonding strength

- Fat contamination of the interface between the tibial tray and the cement

- Failure to cement the keel and only cement the plateau

A study published in the December 31, 2013 edition of Orthopaedic Proceedings found that later cement application to the tray reduced the bonding strength by nearly half. If fat contamination occurred, the interface strength was greatly diminished. However, when the surgeon added cement beneath the tibial tray before an insertion that was fat-contaminated, the interface strength averaged 65 percent.

The study concludes that surgeons can maximize the tibial tray bonding strength by applying cement to the tibial tray just after mixing before the cement is hardened. The entire surface of the tibial tray interface, both plateau and keel, must be thoroughly dry. The keel needs cementing as well as the plateau. Fat is not the only component that can contaminate the process, as blood and saline also cause problems. However, placing cement on the keel minimizes contamination risks.

Although tibial debonding may display no obvious symptoms, it can cause further issues and require additional surgery. Often, debonding can cause knee replacement implants to loosen which can lead to pain and trouble balancing.

Call Us to Discuss Tibial Debonding With Defective Knee Implants

Childers, Schlueter & Smith understands the difficulties involved with tibial debonding in knee replacements and how it can affect your quality of life. Please note, however, that we are no longer pursuing or investigating new knee replacement claims.

Other Knee Implant Lawsuits News

Aseptic loosening, the leading cause of knee replacement failure, can result in pain, reduced mobility, and revision surgery. Learn the causes, risks, and potential treatment options for affected patients.

Knee replacement base plate loosening can cause pain, stiffness, and instability, often requiring revision surgery. Learn how design, sizing, and manufacturer issues may impact implant longevity and patient outcomes.

A bone scan can help determine the condition of a knee joint or implant before replacement or revision surgery, offering surgeons critical diagnostic insights not always visible through standard imaging.

The first lawsuit over premature failure of the DePuy Attune knee implant has been filed, highlighting concerns about tibial base plate loosening and potential widespread complications among patients.

Knee replacement surgery can relieve pain and restore mobility, but some implants, including the DePuy Attune Knee System, have been linked to premature failure and complications requiring revision surgery.

Knee replacements can fail due to infection, wear, or implant defects. Learn the warning signs of knee implant failure and the medical steps you may need to take.